Businesses, original equipment manufacturers (OEMs), field and research techs (both in universities and the private sectore), and more: we have something special for you. It has to do with vehicle emissions monitoring, verification, and reporting.

We’re talking about a helpful and limited emissions verification system called dyno testing.

While this tool may sound like something that’s from Jurassic Park or the Land Before Time movie series, dynos are short for the word “dynamometer.”

If you’ve ever wanted to know about the power, torque, and force of your internal combustion engine (ICE)-powered equipment, you’ll learn more about dyno testing and portable emissions measurement systems (PEMS) here.

Businesses: if you’re looking for better ways to test the power, torque, and force of your ICE-powered equipment — or if you’re just curious to learn more about dyno testing — join us for Dyno Testing 101. We’ll describe everything you need to know about dyno testing to help you make the most of your power equipment — even if you’re on a strict budget.

Let’s roll!

What is a dynamometer?

Before we look at dyno testing, we need to understand the function of a dynamometer. A dynamometer is a piece of automotive or internal combustion engine (ICE)-related equipment that engineers and drivetrain specialists use to assess the basic power, torque, and force of an engine or motor.

The purpose of the dynamometer is to confirm the performance of the engine, equipment, and overall vehicle performance, among other things. Limited examples that a dynamometer can help troubleshoot are:

- When an engine overheats

- If intermittent, performance, or sensor issues exist in a piece of equipment

- The quality of builds, rebuilds, or repairs on a vehicle or piece of equipment in a controlled environment

We recommend using a dynamometer in a controlled environment. Doing so can help you monitor, verify, or report potential issues in the product development lifecycle before your product hits the market. Plus, dynamometers help eliminate pesky variables during testing.

That’s where dynamometer testing — also known as “dyno testing” — comes in handy.

Dyno testing explained

Dynamometer testing — or “dyno testing” — helps operators evaluate the torque, rotational speed, and power generated by a vehicle or engine.

Dyno tests are crucial for research and product development. For businesses in the field of auto-testing, dyno tests help ensure engines are safe and operational before vehicles hit the road.

The way a dyno test works is by measuring the revolutions per minute (RPM) and horsepower of an engine. With a dyno test, a vehicle or engine is placed on rolling drums, pressure is gradually increased, and the engine’s RPM is regulated along with the pressure.

As the engine’s pressure increases, engineers use the dynamometer to collect important engine data on torque, temperature, and other key information needed for vehicle emissions monitoring and ESG reporting.

Depending on the dyno test and the needs of the engineers, engineers can test different types of equipment and collect different types of data.

Common types of dyno testing

Some of the most common types of dyno testing include:

- Engine dyno testing

- Chassis dyno testing

Let’s explore what each is in greater detail.

Engine dynamometer testing

Engine dynos test just what they sound like: engines. Instead of assessing how a vehicle performs under certain conditions, engine dynos test the power of an engine in isolation from the vehicle (or equipment).

Various purposes of an engine dynamometer test include performance, reliability, longevity, and critical factors for modern-day ESG requirements for vehicle efficiency and emissions testing.

Then, the engine dyno uses water brakes and alternating currents (more on these terms in the sections below) to test different loads placed on the engine. These loads “simulate” real-world load conditions.

Chassis dynamometer testing

Often referred to as “rolling roads dynos” or “rolling dynos,” chassis dyno testing assesses the force, torque, and rotational speed of an engine or motor in real-time. In other words, the rollers help “simulate” a real-driving environment (RDE), to the best of their ability.

Chassis dynamometer testing can be used to “simulate” real-life road conditions.

A vehicle is placed on large roller drums with known masses mounted to the bearings of the drums. The car is then tested on these roller drums.

Chassis dyno testing can help businesses and automotive test engineers assess how a vehicle performs before the vehicle hits the market. That way, OEMs and businesses can make better decisions for the vehicle, environment, and company as a whole.

Types of dynamometers

So far, we’ve taken a look at common types of dyno testing. But, we’ve only scratched the surface.

Other types of dynamometers exist when it comes to chassis and dyno testing. These dynamometers include:

- Eddy Current (EC) brake dynamometers

- Water brake dynamometers

- Alternating Current (AC) regenerative dynamometers

Eddy Current (EC) brake dynamometers

If you’re operating lower-power equipment and vehicles, eddy current (EC) brake dyno tests can do the trick. Eddy current (EC) dyno testing uses absorption from the EC brakes to test power equipment.

EC dyno equipment tends to test power equipment that can do up to 250 horsepower (HP).

Power equipment that are low on HP — like lawn blowers, leaf blowers, or chainsaws — may benefit from a dyno test using a simulation in an EC brake dynamometer.

An application of when an EC brake dyno may come in handy is when testing the engine performance and vehicle emissions of a motorcycle.

Water brake dynamometers

These dynos are suited for higher power engines. Water brake dynamometers are used to test engines ranging from 350 to 10,000 horsepower.

A water brake dynamometer may be helpful when testing the emissions output of heavy-duty, off-highway vehicles like locomotives. These dynamometers are best suited to “simulate” loads for large internal combustion and electric engine emissions.

Alternating Current (AC) regenerative dynamometers

This complex dynamometer helps “simulate” a load — and return said load — back to the electric grid. The load is placed on the engine while the dyno measures emissions, temperature, pressure, and other key vehicle metrics.

The dynamometer can absorb the energy produced that’s needed to motor the device. AC regenerative dynos are used to “simulate” — for example — the forces on a vehicle when the vehicle is rolling downhill.

These dynos tend to measure gas and electric-powered engines and vehicles of all different types of horsepower.

Table: types of dynamometer tests (and their use)

| Type of dynamometer | Description |

| Eddy Current (EC) brake dynamometer | 1. Eddy Current (EC) dyno testing uses absorption from the EC brakes to test power equipment 2. Tests power equipment up to 250 horsepower (HP) 3. Compatible with engine and chassis dyno testing |

| Water brake dynamometer | 1. Suited for higher-power engines (think: heavy-duty, off-highway vehicles like locomotives) 2. Tests engines ranging from 350- 10,000 HP 3. Compatible with engine and chassis dyno testing |

| Alternating Current (AC) dynamometers | 1. Absorbs the energy needed to motor the engine and/or vehicle 2. Can simulate the forces on a vehicle when the vehicle is rolling downhill 3. Tests power equipment that range from ten to thousands of horsepower Compatible with engine and chassis dyno testing |

Why do dyno testing?

If you’re an original equipment manufacturer (OEM), service technician, researcher, analyst, manager, or business representative, dyno testing can help you:

- Maximize engine performance and reliability prior to installing an engine in a vehicle

- Measure and verify how a newly rebuilt engine performs

- Identify problems with a vehicle before it’s brought to market

- Minimize the hassle of relying on warranties for possible issues with a rebuilt product

- Assess how the load on the engine affects the engine’s overall performance

But, if your budget is tight, “portable dynamometers” exist. These dynamometers allow you to operate from any location.

That’s right: no need for scheduling time for emissions testing with a brick-and-mortar facility.

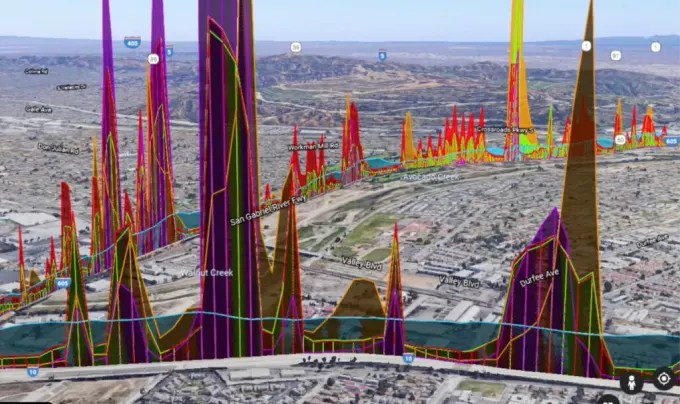

Operators can utilize portable emissions measurement systems (PEMS) from virtually anywhere to gather important diagnostic data on the performance of their engines.

Pro tip: Try portable emissions measurement systems for a seamless engine testing experience

“To add more robust and immediate value (and analysis) to your operation, PEMS, integrated PEMS (iPEMS), and mini-PEMS can be prescribed and utilized on vehicles. PEMS can collect analytical data that are monitored by the driver (and remotely)!” – Earl Leatherland, Operations Manager at GlobalMRV

Looking for more information about dyno testing?

With the global automotive emission test equipment market projected to grow at a compound annual growth rate of 5.1% between 2024-2032, it’s safe to say conducting vehicle and engine emissions tests will become ever more important for business and operations teams.

And the budgets to accomplish these tests will only shrink. Need help sifting through dyno testing options?

GlobalMRV is the industry leader in portable emissions measurement systems (PEMS) and dynamometer testing. In the last six years alone, we’ve collected and analyzed over 3,000 hours of reliable data and helped save OEMs and companies more than $5,000,000 on traditional dynamometer and real driving emissions (RDE) testing for clients of all different industries and niches.

If you’re looking to discuss dyno testing at greater length, contact us today. A member of our team would be happy to discuss the basics (and more!) with you.

Frequently asked questions (FAQ) about dyno testing

What is dyno testing?

A dynamometer test — also known as a “dyno test” — measures the torque and rotational speed of an engine. In dyno testing, operators use a device called a dynamometer that measures the power generated by the vehicle and/or engine.

What types of dyno testing exist?

Some of the most common dyno tests on the market for vehicle and engine emissions testing include:

- Eddy current (EC) brake dyno tests

- Water brake dyno tests

- Alternating current (AC) non-regenerative and regenerative tests

- Chassis dyno tests

- Engine dyno tests

Why assess vehicle emissions output with a dynamometer?

Checking the exhaust emissions of an electric or ICE-powered vehicle can help businesses maximize their efforts in building a quality vehicle that operates smoothly and operates according to environmental compliance and standards.

Dyno testing can save businesses money, time, and effort in maximizing the performance of their ICE, and electric-powered vehicles and engines. Seeking out the expertise of a dyno testing and emissions specialist can help you create a cleaner, more profitable product.